►Mould waterway cleaning machine

Mold, known as "mother of industry", is the core of industrial production such as injection molding, blow molding, extrusion, die casting, etc., which is directly related to the quality of products and the level of production efficiency. Maintenance and maintenance of molds, can directly reduce costs for enterprises, increase efficiency

Mizuken mold waterway cleaning machine adopts the national patent technology, efficient and intelligent cleaning mold waterway, improves product quality, improves production efficiency, and creates new value for enterprises.

►Problems of mould waterway

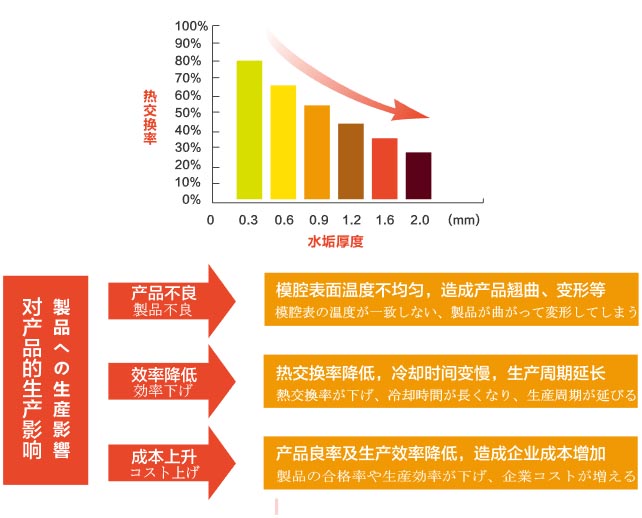

The mold cooling water path is easy to deposit scale, rust, sludge and algae, which makes the cross section of cooling water channel smaller and the cooling channel narrow. It greatly reduces the direct heat exchange rate between the coolant and the mold, seriously affects the cooling effect, makes the molding quality of mold products unstable, increases the defect rate, reduces the production efficiency, and increases the production cost of the enterprise.

According to Philip Kotz, an authoritative institution of refrigeration research in the United States, as long as there is 0.3mm thick scale on the cooling pipe wall, the heat exchange loss will be 21%.

► Technical principle

Mizuken mould waterway cleaning machine adopts the national patent technology. The pulse controller makes the compressed air act on the water flow in the form of pulse, which produces spiral shear force along the inner wall of the pipe, and frequently produces "cavitation" phenomenon. Under the action of alternating pressure, the bubbles in the water will burst, It produces micro jet shock and shock wave shock, which can form a huge impact on the solid surface and cause local surface damage. The jet and the wave generated by bubble burst act on the solid surface with high speed and high pressure to denude it, remove the scaling layer and brittle debris, and make the inner wall of the pipeline be effectively cleaned.

► Benefit analysis

Compared with the cleaning results of 1250t molding machine in a company, the cooling water flow rate and heat exchange efficiency of the mould can be improved completely

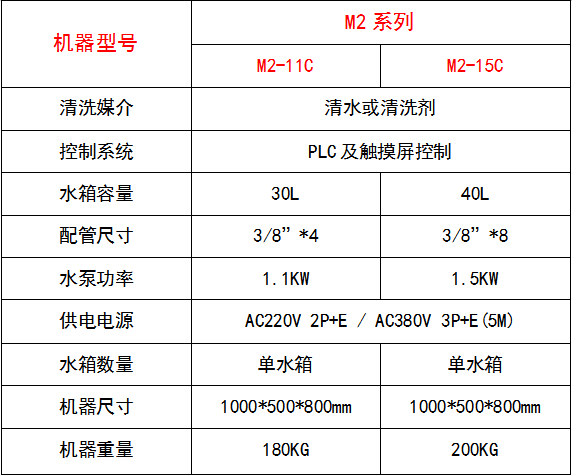

► Specification parameters: